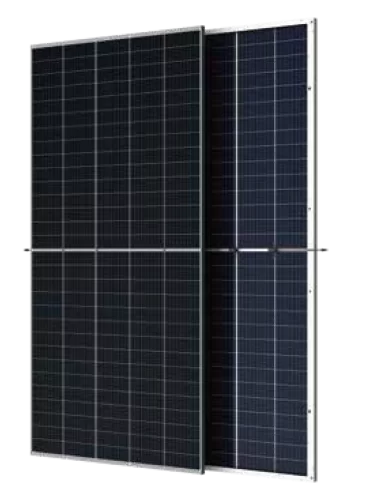

Trina Solar Panels

Dual Glass Monocrystalline

The heat strengthened dual-glass design enables lower degradation rates and higher annual and lifetime energy production that is 25-30 percent higher than traditional framed modules. It does not have a metal frame, so it does not require grounding. It eliminates the cause of Potential Induced Degradation (PID).

The panel can withstand high humidity, high temperatures, sandstorms, ultraviolet and corrosion making it more reliable and durable to ensure a long lifetime much more than 30 years. Together with enhanced performance by PERC technology it leads to greater and quicker energy savings and faster ROI than standard solar panels.

- Robust module construction for snow and wind resistance

The enhanced sandwich design with two 2.5-mm heat-strengthened glasses enable the module to withstand heavy snow load up to 5400 Pa, wind load up to 2400 Pa. - Sand and salt protection

Designed to reduce micro-cracking, UV ageing, degradation and corrosion, the frameless module is ideal for uncompromising weather conditions by blocking moisture permeability and creating higher resistance to sandstorms, salt-mist and ammonia.

Monocrystalline

Monocrystalline PV cells belonging to the first generation of PV cells are made from a single crystal ingot of highly pure molten silicon usually crystalline silicon (c-Si). These PV cells were developed in the 1950s as first generation solar cells. Monocrystalline PV cells use wafers, of about 0.3 mm thick, sawn from an Si ingot of single crystal silicon made by using Czochralski process that was discovered in 1916. It is a method of crystal growth used to obtain single crystals of semiconductors, metals, and salts with the most important application in the growth of large cylindrical ingots of single-crystal silicon. Monocrystalline cells are more expensive to manufacture and typically have a slightly higher efficiency of 15–22% than do conventional polycrystalline cells. Shockley and Queisser, in 1961, calculated the maximum thermodynamic efficiency for the conversion of unconcentrated irradiance into electrical free energy in the radiative limit to be 31%. Monocrystalline PV cells are very efficient, approaching their theoretical efficiency in a semiconductor with bandgaps ranging from about 1.25 to 1.45 eV but are very expensive due to the manufacturing processes used to make them. Mass produced solar cells are less efficient and achieve only 10% efficiency.

Monocrystalline

Monocrystalline PV cells belonging to the first generation of PV cells are made from a single crystal ingot of highly pure molten silicon usually crystalline silicon (c-Si). These PV cells were developed in the 1950s as first generation solar cells. Monocrystalline PV cells use wafers, of about 0.3 mm thick, sawn from an Si ingot of single crystal silicon made by using Czochralski process that was discovered in 1916. It is a method of crystal growth used to obtain single crystals of semiconductors, metals, and salts with the most important application in the growth of large cylindrical ingots of single-crystal silicon. Monocrystalline cells are more expensive to manufacture and typically have a slightly higher efficiency of 15–22% than do conventional polycrystalline cells. Shockley and Queisser, in 1961, calculated the maximum thermodynamic efficiency for the conversion of unconcentrated irradiance into electrical free energy in the radiative limit to be 31%. Monocrystalline PV cells are very efficient, approaching their theoretical efficiency in a semiconductor with bandgaps ranging from about 1.25 to 1.45 eV but are very expensive due to the manufacturing processes used to make them. Mass produced solar cells are less efficient and achieve only 10% efficiency.

Other Models

- DUIMAX Plus

- Honey FRAMED 60-CELL MODULE 2

- Honey Plus FRAMED 60-CELL MODULE

- Tellmax FRAMED 72-CELL MODULE

- Tellmax FRAMED 110 LAYOUT MODULE

- Tellmax Plus FRAMED 72-CELL MODULE(1500V)

- TSM-PC06A